- All products are added to your cart.

LOTO Procedures

Lockout tagout procedures

Thousands of work accidents occur while repairing or servicing industrial equipment. Most of those accidents are due to energy sources that have not been isolated. Therefore, identification of the equipment’s potential hazard is essential for a successful lockout-tagout procedure. On this page you will find both an overview of the valid regulations as well as an action plan for the implementation of your lockout-tagout procedures.

OSHA Standards

Many international iompanies have adopted OSHA standards to control lock-out tag-out procedures. Lockout-tagout-shop.com provides all the products needed to be OSHA compliant. OSHA Standard 1910.147 relates to lock-out tag-out and the control of hazardous energy. Four key points of the OSHA lock-out standard are:

1. Devices must be identifiable

2. Devices shall only be used for controlling energy

3. Devices hall not be used for other purposes

4. Devices shall meet the following requirements: durable, standardised, substantial, identifiable

Regulations in Europe

EEG89/655 Article 19 : “The employer is committed to guarantee the safety and protection of employees and to take the necessary measures to reduce risks to the minimum possible”.

Article 46 : “The employer must ensure that all safety procedures are strictly implemented and regularly reviewed by appropriate means”. “Employees must use all necessary tools to carry out maintenance they are responsible for and to aid them in the case of accident or emergency”.

Article 49 : “When carrying out isolated maintenance, the equipment must be clearly labelled”. “Isolation of equipment from all possible electrical energy sources; lock-out of devices in the ‘off’ position; verification of isolation of all energy sources close to the maintenance area”.

The risks

The risks to which employees are exposed can be mechanical or related to the energy sources powering the machine. If these energy sources are not isolated, the equipment can be accidentally restarted. There is a wide variety of energy sources which require isolation. Common examples include:

1. electricity

2. hydraulic pressure

3. compressed air

4. gas

5. steam

6. and all types of fluids

Important lockout tagout procedures

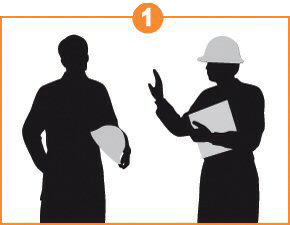

1. Coordination

All interventions need to be discussed in advance with the team to define the nature and duration of the work and the equipment which needs to be locked out.

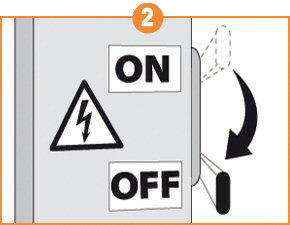

2. Separation

Stop the machine. Warning: simply activating the emergency stop device or control circuit is not sufficient to protect employees; the energy must be completely isolated at the source. Make sure that there is no residual energy.

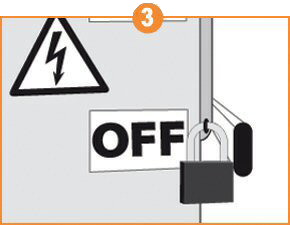

3. Lock-out

The isolation point that allows the separation must be immobilised in open or closed position according to the instructions or the planned procedures.

4. Verification

Check that the device is properly locked out with: starting attempt, visual check of the presence of lock-out system or measuring devices identifying the absence of voltage, pressure and flow.

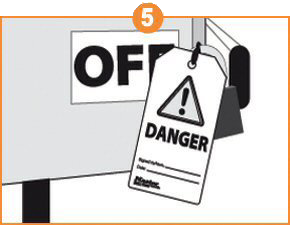

5. Notification

The locked out equipments must be identified with specific tags informing that interventions is in progress and that it is forbidden to unlock the equipment.

6. Immobilisation

Any mobile elementof a working equipment must be mechanically immobilised by locking, pinning or blocking.

7. Road marking

The working zones where there is a risk of falling must be clearly indicated and marked out. The access in a hazardous area must be forbidden.

The solution

Therefore, the Lockout-tagout-shop.com products are made from high resistant material offering: temperature resistance, chemical resistance, corrosion resistance and UV stability. Master Lock Safety Series™ lock-out systems are easy to use, intuitive, easily storable and assure safe and efficient isolation of the energy source.

Safety Series™ Lock-out systems are compliant with regulations: “1 employee – 1 padlock – 1 key”. Each user has their own key. They are the only one to be able to open their personal safety padlock.

Lockout-tagout-shop.co.uk is concerned with employees’ safety and therefore uses its experience in the padlock profession to develop new lock-out systems to provide solutions for technicians safety needs.